Build, Supply, Install & Service

Build, Supply, Install & Service

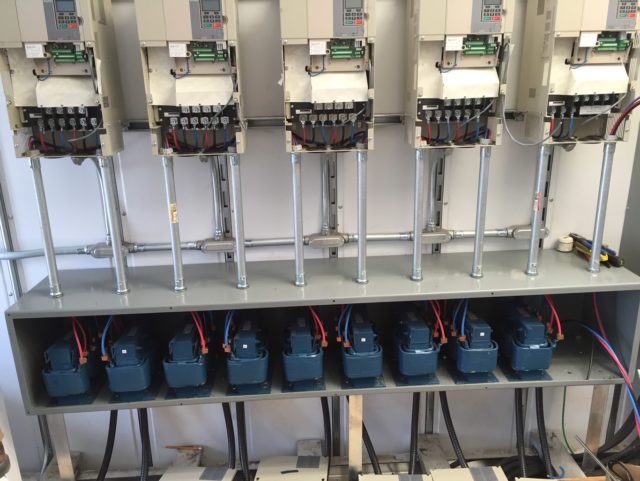

Custom enclosures give you the ability to expand your operations. They can be pre-built and tested in house and then brought to site for installation, limiting your downtime.

Custom build features include:

A proper ground is crucial to a safe and effective electrical system but is often overlooked or installed incorrectly. Proper grounding of equipment prevents user contact with dangerous voltage if any electrical insulation fails or a live conductor comes in contact with metal parts. Proper grounding also dissipates any static charge that builds up which can cause damage to electronic components.

A.E.S. can test your grounding system with our certified and calibrated Fluke 1623-2 ground tester and determine if your ground resistance is adequate for your operations.

Sea-can builds offer customers a portable, protected and cost-effective option. They can be constructed as miniature MCC control centers, power distribution points, capacitor bank tie-in points or expansion solutions for your growing operations.

Speed control is vital to particular pieces of equipment on your operation. Variable speed drives allow operators to make large or incremental adjustments to their operations on the fly.

Features include:

Soft-starts provide the ability to bring large motors on-line with smaller generators or cut out nasty peak power draw sur-charges on your high-line power bill.

Features include:

A.E.S. can assist with a variety of systems for your operations

Metal Detectors – Tramp metal can be detected before it enters any crushing equipment and cause damage. Metal detectors can be interlocked with the conveyor so when tramp metal is detected the conveyor will stop or an audible/visual warning will notify an operator that metal has been detected.

Belt Speed Sensors – Belt slippage or a conveyor stopping without notice can be eliminated with the installation of a belt speed sensor. Sensors can be set to a predetermined speed and if the belt speed drops below that pre-set value an audible/visual alarm will notify the operator.

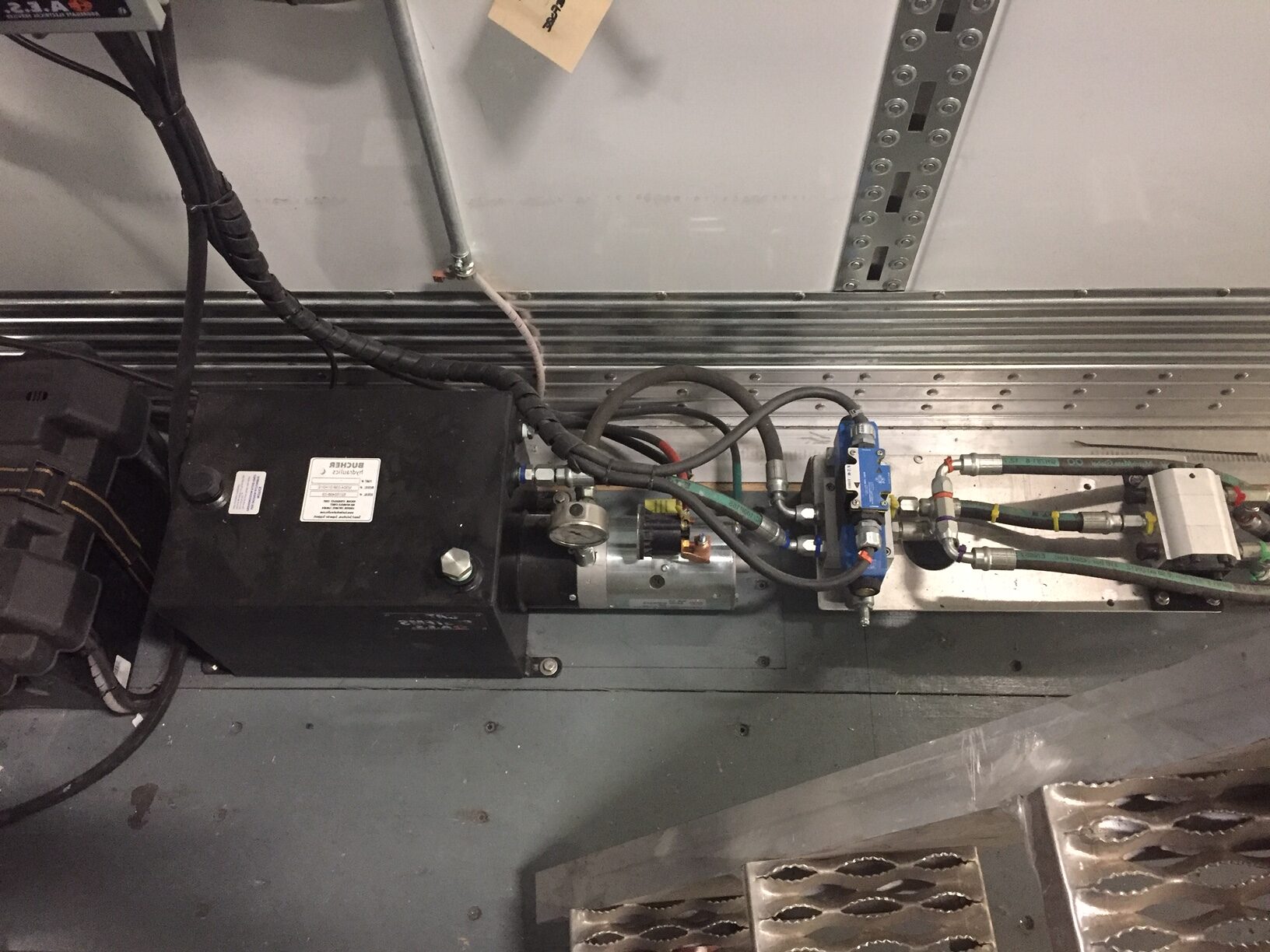

Electro-Hydraulics – We can design/source and install systems for various applications at your operation whether it be your Cones, Jaws, Impactors, Raise/Lower or Folding Conveyors, Parts, Valves, Controls – right down to crimping and soldering your hydraulic lines.

Belt Scales – Conveyor belt scales can be installed on belts from 24” to 60” and can accurately weigh the products being conveyed. Scale readouts can either be mounted directly on the conveyer or installed in any location via remote cable.

Air Solenoid Systems – Increase load times at your powder silo’s by agitating compacted powder in the silo’s. Use electrical over pneumatic controls for moving equipment components or mechanical lock features.

Concrete Powder Sites – Full install and electrical termination of drop down powder loading chutes. Fully customized control centers for multiple SIW’s integrated with weight scale loadings

A.E.S. can provide electrical parts from most major brands including:

Allen Bradley, Cutler Hammer, Square D, Appleton, Eaton, Techspan, Crouse-Hinds, T&B, Omron, Mersen, Benshaw, Schneider, ABB, Siemens, Phoenix, Cooper, Leviton, Intermatic, Yaskawa, Yokogawa, Mitsubishi, Hoffman, Hammond, Hubbell, Tele-Fonika, General Cable, Southwire, and numerous others.

Parts Include: